| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | RUISEN |

| Delivery Time : | 60-90DAYS |

Steel And Aluminum Explosive Bonding Timetallic Transtion Joints Clad Strips For Shipbuilding

Advantages for shipbuilding and other structure connection purposes

Corrosion resistance:

Aluminum has good corrosion resistance, especially in marine

environments. By using aluminum-steel transition joints, the

structure can benefit from the corrosion resistance of aluminum in

areas exposed to seawater or other corrosive elements.

For example, on ship hulls, the use of these joints can help

prolong the lifespan of the vessel by reducing the effects of

corrosion.

Lightweight yet strong:

Aluminum is lighter than steel, which can help reduce the overall

weight of the ship or structure. This is crucial for improving fuel

efficiency in ships and making transportation and installation of

structures easier.

In shipbuilding, a lighter weight can increase cargo capacity or

improve the ship's speed and maneuverability.

Good electrical conductivity:

Aluminum has high electrical conductivity, which can be beneficial

in certain applications where electrical conduction is required.

For example, in some marine electrical systems, the use of aluminum

components connected by these transition joints can ensure

efficient electrical flow.

Cost-effective:

Although the initial cost of explosive welding transition joints

may be higher than traditional connection methods, their long-term

durability and performance can lead to cost savings over the life

of the ship or structure.

Reduced maintenance and repair costs due to better corrosion

resistance and strength can offset the initial investment.

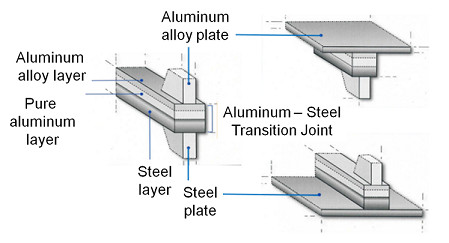

Bimetallic or Triametallic transition joints accordingly.

- Steel (Q235B, 316L, 304) + Aluminum (AL1050 or 1060) + Aluminum alloy 5083

- Steel (Q235B, 316L, 304) + Aluminum (AL1050 or 1060) + Aluminum alloy 5083

Total thickness can be from 10 mm till 40 mm

The benefit of the last one combination is the ability for the interface to be heated up to 500 °C during fusion welding to ship structure. Meanwhile the first one combination interface can be heated only up to 300 °C

|